In the semiconductor industry, the need to achieve optimal results from every aspect of manufacturing is absolutely critical. In fact, the sub-micron technology of today’s wafers makes dicing and die processing more critical than ever. Keteca is meeting this challenge todaywith our Diamaflowproduct line of coolant additives and dispensing systems.

Diamaflow

Challenges Created by Dicing:

Today’s use of larger silicon wafers and smaller die in the semiconductor industry have made it more difficult to remove silicon dust from the wafer and bonding pads after dicing. This leads to:

- Longer sawing time.

- More silicon dust accumulation on bonding pads.

- Possible galvanic corrosion on Al/Cu bonding pads.

The Solution For Wafer Dicing:

Diamaflow dicing solutions are formulated by Keteca USA., Inc. to specifically solve the problem of silicon dust on semiconductor wafers after the die separation process.Diamaflow dicing solutions are formulated using several special precision cleaning, surface-active, non-ionic surfactants, each selected for a specific purpose.

Diamaflow dicing solutions introduced to the DI dicing water by our Automatic Dispensing Systems (ADS) will help:

- Prevent silicon dust build-up on bonding pads by reducing the surface tension up to 50%.

- Remove the silicon dust from the cut, encapsulates the individual piece of dust and floats the contamination off the wafer during the dicing and wafer washing process

- Prevent galvanic corrosion on Al/Cu bonding pads

- Reduce heat and friction during dicing.

- Reduce chipping on top and bottom side of the wafer.

- Keep the dicing blade clean and increase the cutting life of the dicing blade.

- Improve ball shear strength.

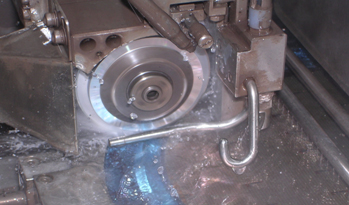

Automatic Dispensing System (ADS)

Our ADS are designed to deliver a constant mixture of Diamaflow with D.I water before delivery to the wafer saw machine. And our ADS has the following unique features of :

- Easy/Fast Installation.

- User Friendly.

- Compatible with all makes of dicing saws.

- Minimal maintenance required.

- Constructed with polypropylene to meet the requirements of clean room classifications

ADS systems come in a variety of models, ranging from the support of two dicing saws (ADS-2) to a maximum of six dicing saws (ADS-6).